Nanoengineered mirrors convert infrared photons’ heat into light.

Infrared radiation, i.e., invisible light with a long wave length, is carried by photons. Miniaturized synthetic crystals, called photonic crystals, are made to recycle heat from infrared radiation, and convert the heat to light. It’s a nanoengineered process developed at MIT. The intricate engineering of the tungsten filament, demonstrated by Bill Hammack in the video on the preceding page, seems equalled or exceeded by this nanotechnology.

Tungston versus photonic crystals

Here is what Mattack, the “engineerguy,” said about the tungston process:

To make tungsten ductile it took elegant, creative and careful work by an engineer at General Electric. William Coolidge developed a process for taking tungsten powder and making it into a wire.

Just to give you an idea of the difficulty here’s an abbreviated list of the steps One, apply great pressure to turn tungsten powder into a fragile bar. Two, heat it to 1300 degrees Celsius and then cool with water. Three, pass a current through the tungsten while heating it to 3200 degree Celsius, & then cool again. Four, heat yet again to 1500 degree Celsius, but this time while flowing hydrogen over it. Five, pass it through a series of dies to cold work it and then hammer it. And then the sixth and final step: heat it and then reduce the temperature gradually while drawing it into a 1 mm diameter wire.

Compare that to the nanoengineering process which claims to be bringing back the incandescent bulb:

The solid state physics of photonic crystals

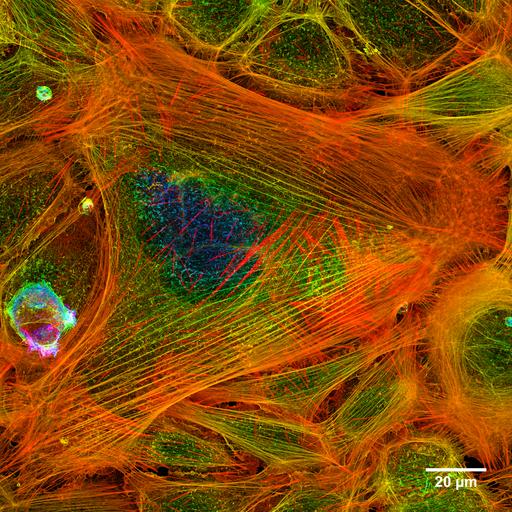

Here’s how nanoengineering is reinventing the incandescent light bulb using photonic crystals. To really visualize this technology, one could read tutorials on the web about photonic crystals, which Scientific American has characterized as “semiconductors of light” in an article on optoelectronics./

Thomas Edison would be pleased. Researchers have come up with a way to dramatically improve the efficiency of his signature invention, the incandescent light bulb. The approach uses nanoengineered mirrors to recycle much of the heat produced by the filament and convert it into additional visible light. The new-age incandescents are still far from a commercial product, but their efficiency is already nearly as good as commercial LED bulbs, while still maintaining a warm old-fashioned glow.

“This is beautiful work,” says Shawn-Yu Lin, an electrical engineer and optics expert at the Rensselaer Polytechnic Institute in Troy, New York. He and others note that there is plenty of room for further improving the mirrors, which could ultimately push the efficiency of the bulbs well beyond what is possible with today’s lighting technologies. And because lighting consumes 11% of all electricity in the United States, any such improvement could dramatically lower energy use, and, by extension, the carbon dioxide emissions that contribute to climate change.

Incandescent lights have changed little since Edison first perfected them. The bulbs work by sending electricity through a curly tungsten filament. The long, twisting path increases the electrical resistance faced by traveling electrons, heating the filament to some 3000 K. At that temperature, the filament glows with the warm yellowish white light that we’ve come to expect from light bulbs.

Still, only about 2% of the energy fed into an incandescent is emitted at visible wavelengths. Most of its output is at longer infrared (IR) wavelengths and is wasted as heat. Other technologies do somewhat better. Compact fluorescent bulbs typically reach an efficiency between 7% and 13%; LEDs manage between 5% and 15%. But so far, these types of bulbs have had trouble producing the warm white light that most consumers prefer.

Researchers have tried to boost the efficiency of some light emitters by sculpting the surface of the emitting material with nanostructures designed to emit more energy as visible light. But with incandescent bulbs, the tungsten filament’s scorching temperature quickly causes such nanostructures to fall apart.

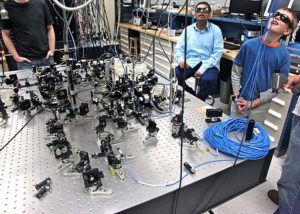

Read about the above engineering apparatus for viewing photonic light photographed by Steve Jurvetson from Menlo Park, USA (Unweaving the Rainbow) via Wikimedia Commons.

To read the rest of this article visit sciencemag.org.

Image attribution: Wikimedia Commons